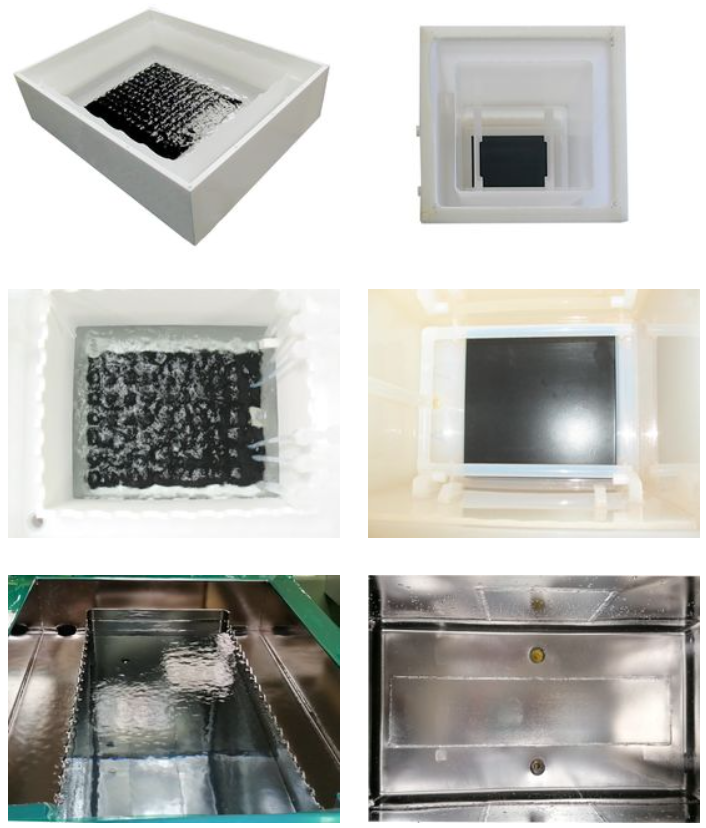

There is a variety of tanks used in wet processes, e.g. in VA (stainless steel) or PVDF. The integration of the transducer plate is done by screwing in or welding and hence becomes an integral part of the tank. In the tank design process a cutout for the transducer plate is foreseen and later practically integrated at SONOSYS® finally.

The requirements of the used medium (chemicals) usually define which material is used both for the tank and the coating of the Megasonic transducer. We are glad to offer you counceling around the topic of how to select the right material and integration method, please feel free to reach out to us.

Example application:

The Megasonic system has been developed especially for wet processes in the semiconductor wafer production. With a focus on SC1 and SC2 processes, as well as final rinse, a temperature range or approx. 20C to 70C is covered (up to 300m/12" wafer).